Printed electronics

Revolutionize your products!

Memtronik are unique in their ability to print electronic circuits on a wide variety of previously inaccessible substrates. There are an increasing number of commercial applications available on the market.

Our engineering and research and development team can guide you through the process of bringing your printed electronics projects to life, from packaging to smart clothing including IoT.

Receive a quote in 48 hours

Printed electronics offer many advantages:

- Less expensive than traditional electronic component development processes

- Possibility to print on large surfaces

- Unlimited potential for customization

- Use of transparent, flexible, or elastic substrates

- Environmentally-friendly production process

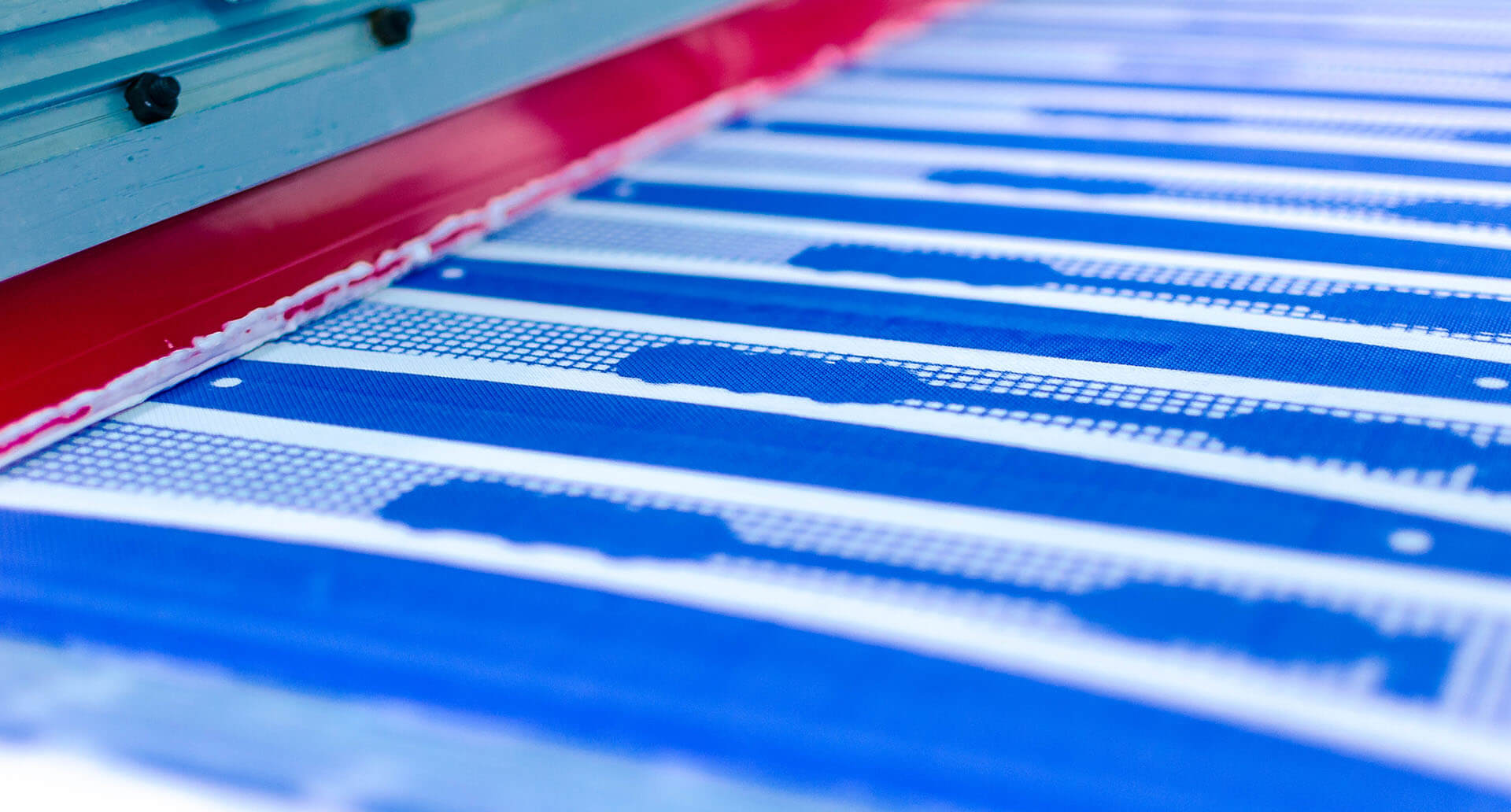

- Roll printing

Printed glue for peak performance

By developing a process that allows us to print adhesives and spacers directly onto rolls, we can deliver products of superior quality at an unbeatable price (prices that were previously only an option if you outsourced your manufacturing to other countries!). There are many different types of adhesives and spacers available to help your circuits and sensors integrate perfectly with your adhesion surface, while adhering to environmental standards.

Here is a snapshot of the main commercial applications being developed by our engineering team. Our technical our savvy doesn’t stop there: if you can dream it, we can make it happen!

- Heated elements (clothing, floors, etc.)

- Smart packaging (medical, food, etc.)

- Smart clothing (circuits integrated into clothing items)

- Sensors (biometrics, pressure, ECG, etc.)

- Antenna (wide range of frequencies)

- Projected capacitive touch screens (glossy, antireflective, multi-touch, etc.)

- Resistive screens (glossy, antireflective, 4 / 5 / 8 wires, etc.)

Discover our other products

Our latest publications

An inside look at the manufacturing process of a high-precision overlay for the medical industry

When it comes to human-machine interfaces (HMIs) intended for the medical and pharmaceutical sectors, state-of-the-art technologies are vital to the manufacturing process. After all, achieving superior reliability and precision is the ultimate goal! Strict standards...

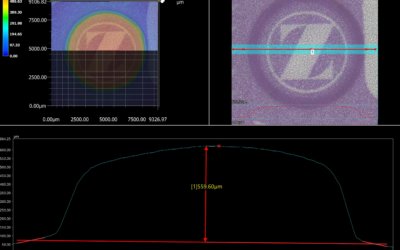

How to ensure your product is optimized and meets your needs

Whether you’re at the prototyping stage, the scaling stage or during production, Memtronik can offer you a combination of tests and trials to evaluate the performance of your product, or to monitor certain parameters with these 5 types of laboratory trials. Why should...

How to choose an eco-responsible manufacturer

For many companies, when it comes to choosing a manufacturer for your projects, eco-responsibility is a very important criterion. Whether it is in terms of infrastructure, production, processes, or supply methods, which measures does your potential partner take to...

Put Us to the Test!

Custom graphic overlay, membrane switch/capacitive switch, touch screens or printed electronics like FSR, biosensors, heaters and more! No matter the project, you will have a quote in-hand within 48 hours!

Looking for a Partner?

Do you have a complex project that needs the involvement of a partner able to deliver a truly personalized product?